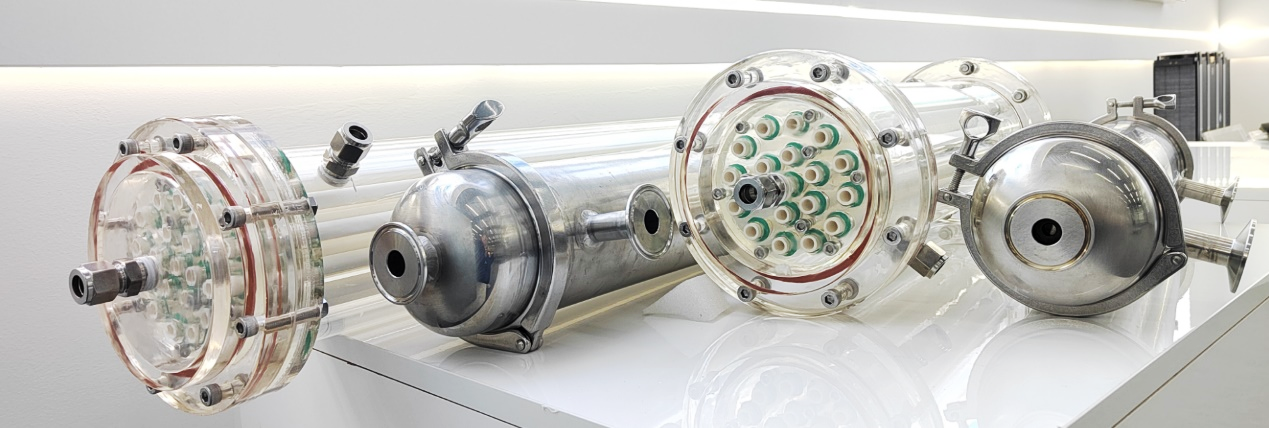

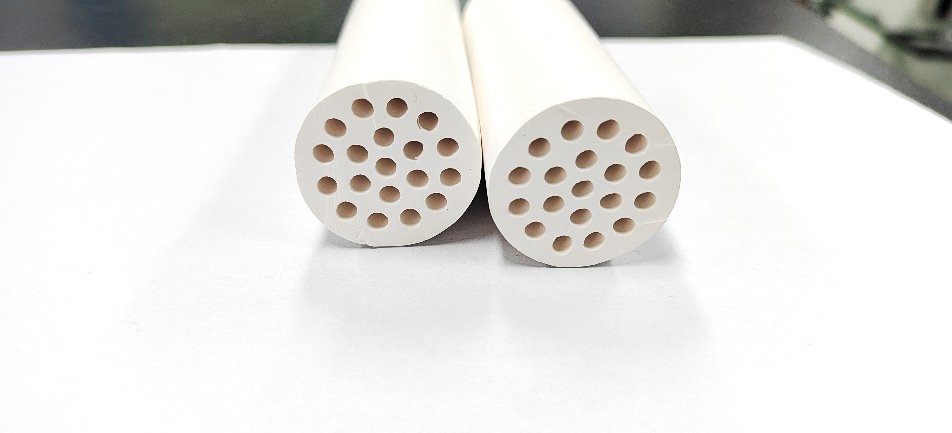

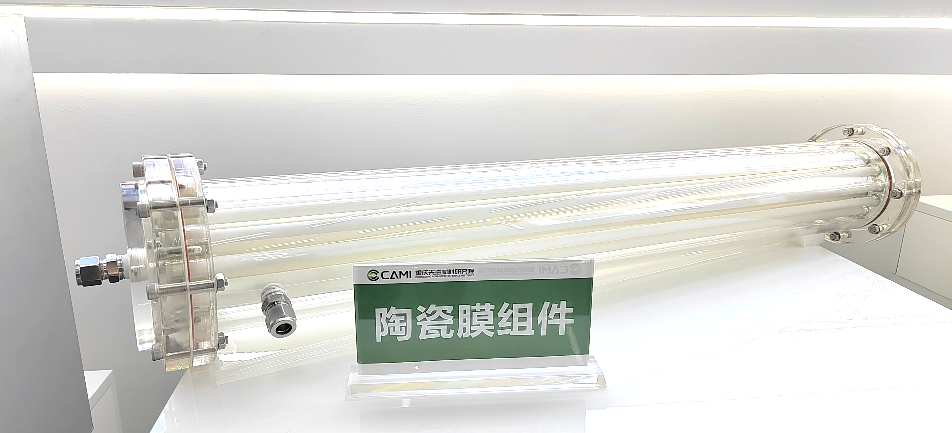

Ceramic membrane is a high-precision filtration membrane produced by high-temperature sintering and various post-treatment processes using inorganic raw materials, such as alumina, titanium oxide, and zirconia. MOF empowers the ceramic membranes with balanced filtration speed and separation precision, making the products ideal solutions for various industries involving separation and recovery process, such as wastewater treatment, liquid sterilization, seawater desalination, lithium extraction, carbon capture, electronic special gas, VOCs separation, and high-temperature gas dust removal.

Product features:

● High stability: acid and alkali resistance, oxidation resistance, organic solvent resistance, low temperature resistance, high temperature resistance, heat shock resistance, biological and environmental degradation resistance;

● High filtration accuracy: Select high-quality ceramic raw materials, develop advanced membrane making processes, reduce pore size defects, and narrow pore size distribution;

● High porosity: The porosity can reach over 45%, and it has ultra-high permeability under the same pore size conditions;

● Low cost: independently developed automated film production line with high yield and stable performance, capable of regenerating and recovering ceramic films;

Application scope:

●Food and beverage industry (decolorization and purification of sugarcane sugar, extraction and purification of effective ingredients in tobacco extracts, high-temperature extraction of effective ingredients in traditional Chinese medicine, etc.)

● Biopharmaceutical industry (purification of lincomycin alkaline solution, desalination and impurity removal of iron dextran, etc.)

● Petrochemical industry (oilfield produced water treatment, chemical fiber alkaline solution reuse, etc.)

● Environmental protection industry (oily wastewater treatment, municipal wastewater treatment, industrial wastewater treatment, etc.)