The material revolution is the most important driving force to promote the progress of human civilization, technological development, and industry upgrading. The study of new materials deepens our understanding about materials properties and expands fields of materials applications.

The MOFilter molecular intelligence technology is a combined innovation of interdisciplinary research led by Professor Bo Wang from Beijing Institute of Technology, awardee of the Leading Talent of The National Ten Thousand Talents Program and the recipient of The National Science Fund for Distinguished Young Scholars. The technology has found first successful commercialization in hydrogen fuel cars and air purifiers, breaking foreign technological monopolies through independent technological innovation. CAMI has applied for more than 150 patents, 50 of which has been authorized, with over 30 new patents added each year. The sound intellectual property protection strategy not only lays a solid foundation for the industrial innovation, but also enables the continuous breakthroughs in industrial applications.

The porous structure of MOF materials, the coordination of metal centers and organic ligands, and other forces work together to give them an ultra-high specific surface area (over 7000m2/g). The unfolded area of one gram of MOF material is larger than a standard football field, far larger than traditional activated carbon and nano zeolite molecular sieves, providing a wide range of application prospects in gas adsorption, catalysis, separation, and drug delivery.

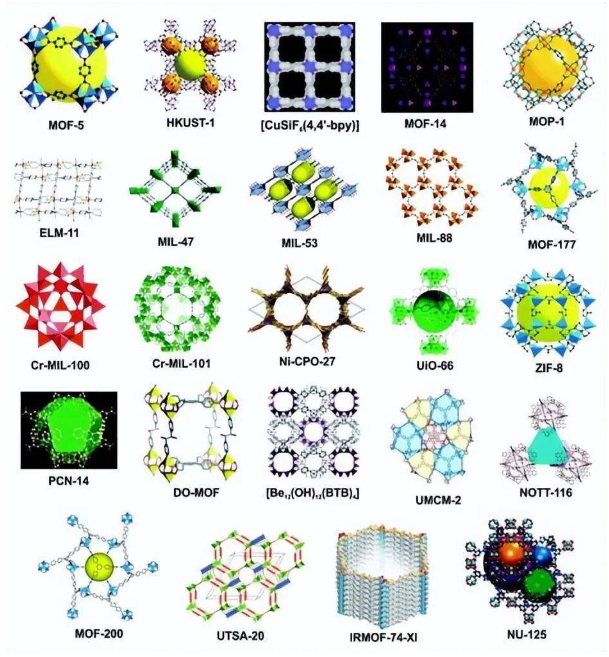

The pore structure of metal organic frameworks (MOFs) has a high degree of designability. By selecting different organic ligands and metal centers, we can regulate the pore size, shape, and surface properties of MOFs, which enables us to customize MOF materials for different purposes.

MOF ligands can be divided into carboxylic acid MOF ligands, nitrogen-containing MOF ligands, carboxylic acid nitrogen-containing mixed MOF ligands, halogen MOF ligands, hydroxyl MOF ligands, etc. based on their different organic ligands. Various MOFs can be designed based on metal coordination numbers and organic ligand structures, and unique functionalities can be endowed to MOFs by introducing additional functional groups onto organic ligands.

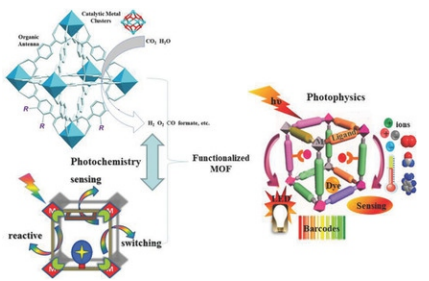

MOF materials have abundant active sites, which can achieve multi site synergistic catalysis, bringing revolutionary impact to the development and application of catalytic technology, and are expected to play an important role in future catalytic industrial applications.

In 1999, Professor Omar Yaghi reported the first example of MOF material, a three-dimensional open framework constructed from rigid organic ligand terephthalic acid and transition metal zinc, currently known as MOF-5. The framework remained intact even after removing guest molecules from their vast volume of pores. After then, MOF materials experienced a rapid development, with over tens of thousands of new species with diverse structures and adjustable performance. Representative examples include IRMOF, ZIF, MIL, UiO, HKUST, CAU, PCN, UTSA, NOTT, BUT, BUC series etc. MOFs

feature high specific surface area, high porosity, ordered pore structure, adjustable pore physicochemical properties, and abundant open active sites. They have shown promising application potentials in many fields of applications, such as gas adsorption, molecular storage and separation, biomedicine, blood purification, air filtration, etc.