In the semiconductor manufacturing process, elimination of airborne molecular contamination (AMC) is crucially important, as these small molecules can have a negative impact on the performance of semiconductor devices, such as reducing charge carrier mobility, increasing leaking current, and reducing device reliability. AMC includes various volatile organic compounds (VOCs), acids, bases, and other chemical vapors that may come from the wear and tear of chemicals, solvents, cleaning agents, or equipment during the production process.

MOFs with unique structure and performance bring new solutions for AMC elimination, as their high specific surface area, adjustable pore size, and functionalized surface chemical properties enable them to effectively capture and immobilize various target pollutants, thereby improving filtration efficiency.

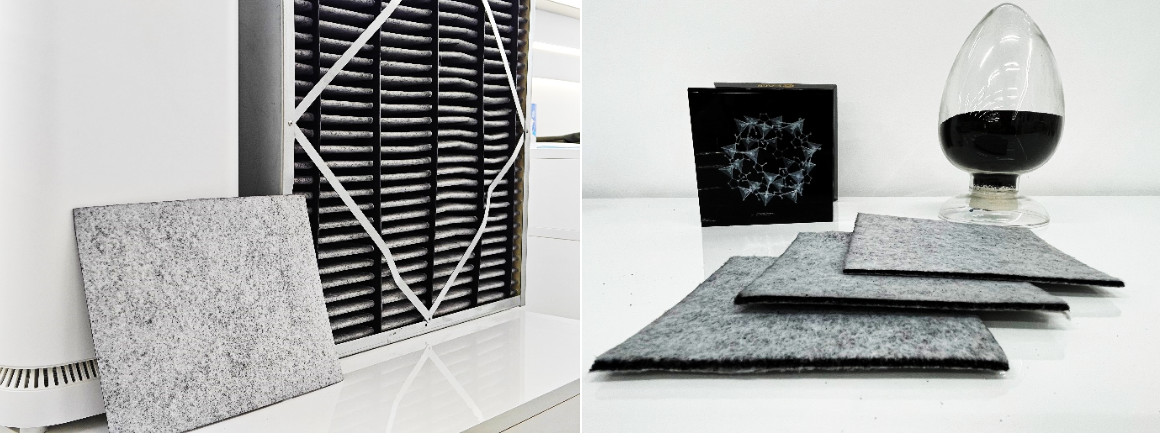

Product features:

●Wide applicability: can selectively adsorb all three major types of pollutants, including acid (SO2 and H2S), alkaline (NH3), and VOC (toluene, acetone, isopropanol, etc).

●High adsorption capacity: the adsorption capacities against acid and alkaline are 1.7 times and 1.4 times higher than imported materials, respectively.

●Collaborative elimination.: Fine particulate matter and AMC are synergistically removed.

●Low concentration (ppb/ppt level) adsorption: works well for low concentration of ppb and ppt level with high filtration efficiency and low air resistance, effectively reducing energy consumption.

●Facile process: The production process is facile and odorless.

Main performance parameters

|

Filter material category |

Resistance/pa |

Initial efficiency/% |

Cutoff efficiency/% |

|

Super filtration materials for acidic gas pollutants |

ninety-three |

ninety-nine point nine nine |

eighty |

|

Alkaline gas pollutant ultrafiltration material |

ninety-seven |

ninety-nine point nine nine |

eighty |

application area

AMC gas pollutant filtration in clean rooms, including semiconductor, pharmaceutical, biochemical protection, military and other fields.